Benefit of PdM

You probably may have heard all about the benefits of predictive maintenance before. But If you have only heard and could not understand what is this, then let us break it down for you! Proponent of PdM points to two key benefits: 1) saving of un-necessary inspection/repairs resulting in more lifetime and less expenses, and 2) reduction in downtime. On the other hand, reactive maintenance (RM) comes with high costs and it doesn’t avoid downtime.

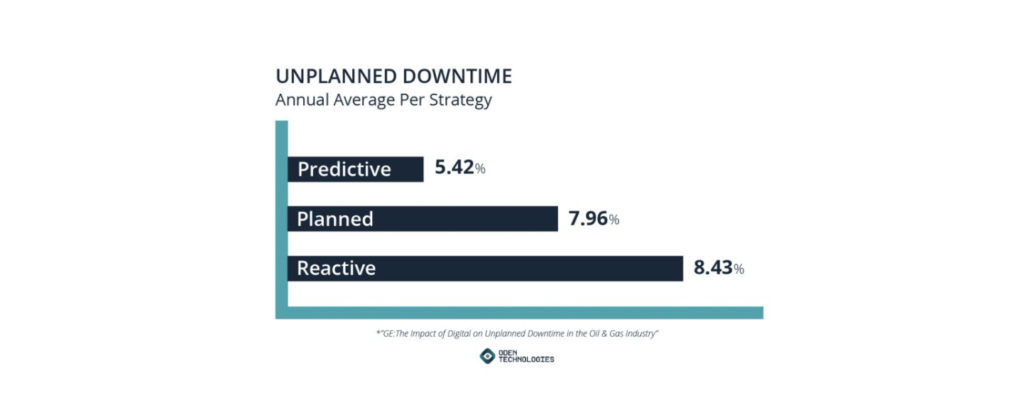

So IF predictive maintenance can eliminate hours of downtime, it might pay for itself with higher outputs and reliability. As an example, here’s the average unplanned downtime in the Oil and Gas Industry:

Challenges in PdM

So first question you have to ask yourself: is extra 1-2% gain in availability/utilization worth the money you will be spending?. Second and most importantly, you have to ensure that the tools and system you will implement should be really able to detect failures accurately and avoid breakdowns.

Any body working in this field would know that the Predictive maintenance is more targeted, but it isn’t foolproof. How accurate is it? What’s the likelihood of predicting failures? And can you predict them with enough time?. All of it depends upon what you buy and how much initiative you take in successful implementation!